Environmental Sustainability

As a global citizen, Chenbro actively promotes a low-carbon culture within the company, dedicated to achieving the 2050 Net Zero Transition goal.

Climate Change Management

In 2024, Chenbro's HQ, Chiayi factory(CTC),Chen-Feng Precision (CTW), Chenbro Technology (CSH) and Procase Electronic (Dongguan) all obtained ISO 14064-1 verification.

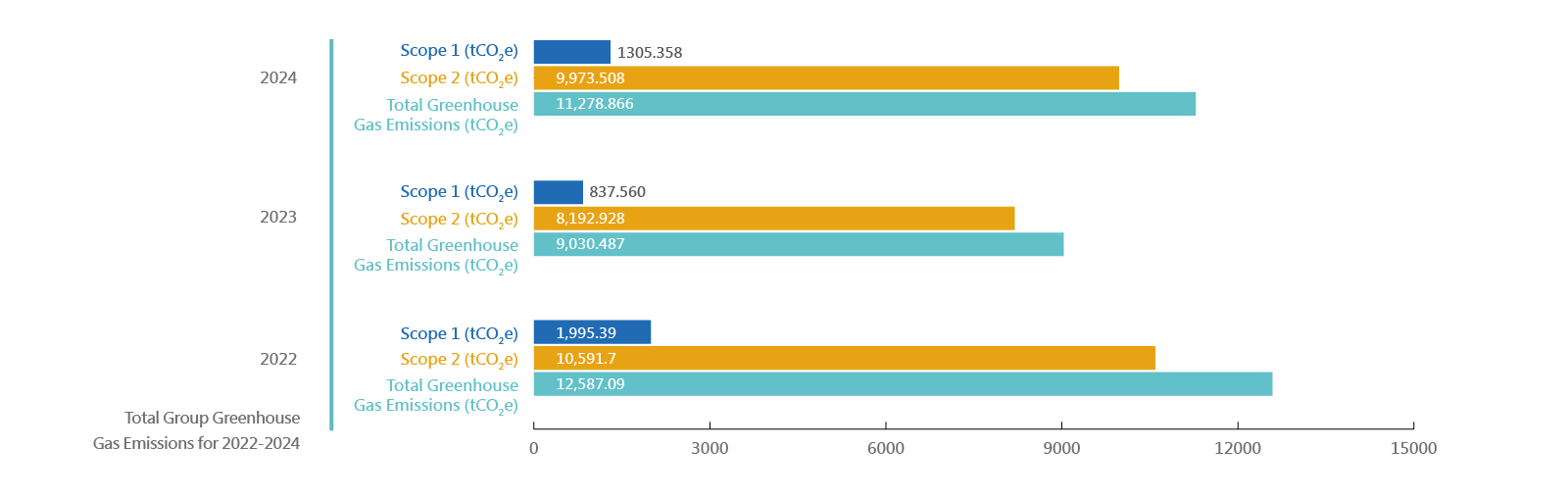

Greenhouse Gas Management

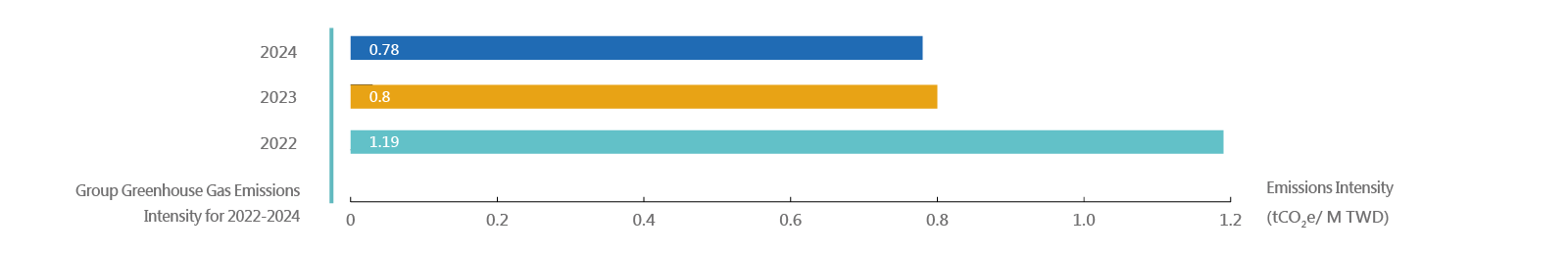

The following 2024 Carbon Emissions data covers its headquarters, Chiayi factory, Chenbro Technology (Kunshan), Procase Electronic (Dongguan), Chen-Feng Precision(Wugu) , USA office ,Germany office and Chinaoffice. The inventory covered Scope 1 (direct greenhouse gas emissions) and Scope 2 (energy indirect greenhouse gas emissions). Scope 3 (other indirect emissions) was not included in the 2024 inventory due to the difficulty in obtaining information and because these emissions are not within the organization's control. The total greenhouse gas emissions for the group significantly decreased in 2024, with an emissions intensity of 0.78. Due to the addition of new plant locations in the 2023 reporting boundary, the baseline year has been reset to 2024, with a target set to reduce emissions intensity by 24% by 2030.

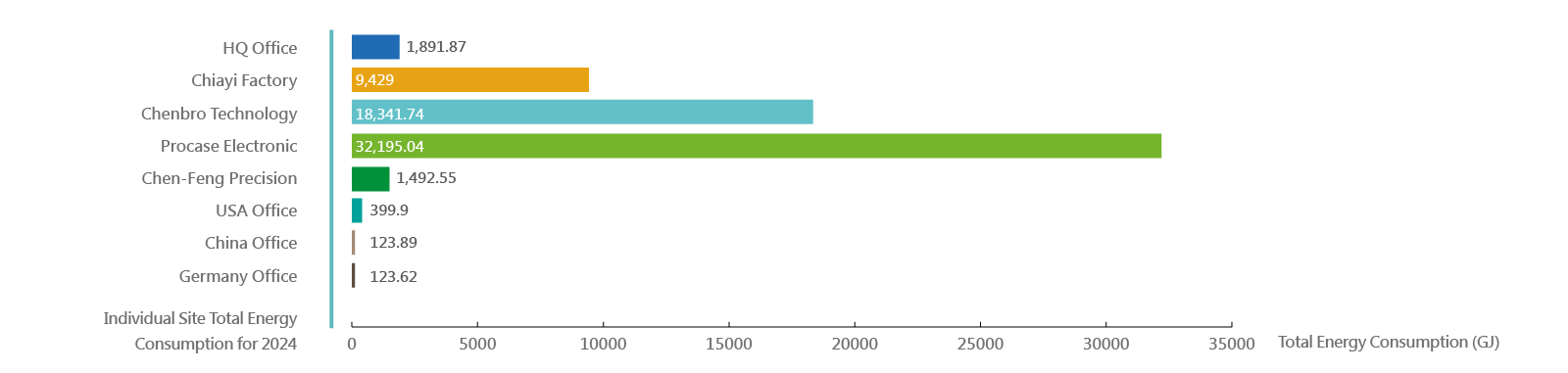

Energy Management

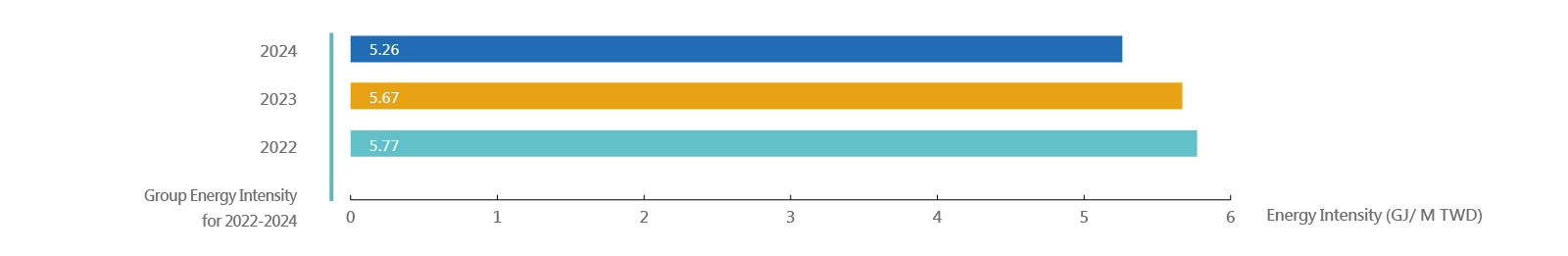

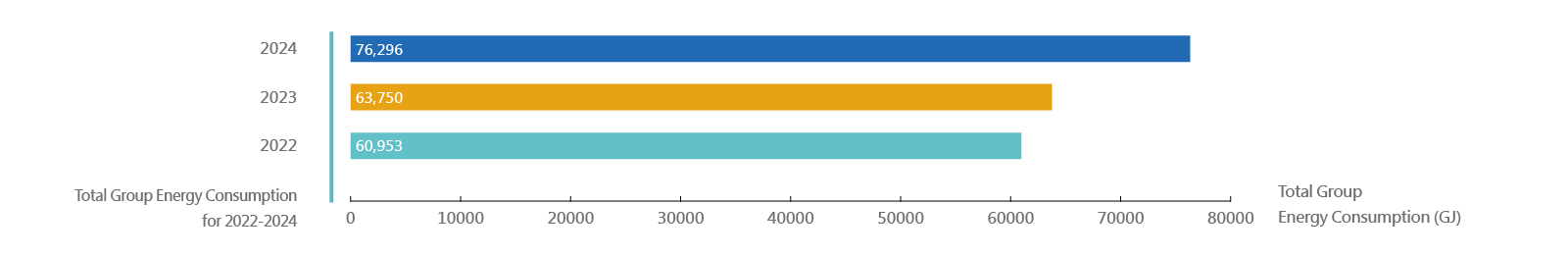

Chenbro's energy intensity is expressed as total energy usage divided by annual revenue. In 2024, the energy intensity was 5.26. Both the total energy usage and energy intensity from the inventory have shown a decreasing trend year by year.

Chenbro is committed to creating an environmentally friendly office space, advancing business performance in a climate-friendly and cost-effective manner, and gradually implementing this approach in every business operation.

Annual plans include:

- Replacing high-energy-consuming equipment and introducing automation processes in factories to improve efficiency and reduce energy consumption.

- Implementing air conditioning temperature and time controls in offices, turning off lights during lunch breaks, and practicing energy conservation.

- Purchasing eco-friendly LED lighting with environmental certifications, energy-saving variable-frequency air conditioners, and utilizing solar power.

- Designing the Chiayi plant with a 9-meter-high interior and low-radiation glass to reduce air conditioning use and establish an energy-efficient cooling framework.

- Implementing an ice storage system at the Chiayi plant to store cooling energy during off-peak hours and use it during peak load periods. This approach reduces electricity waste during off-peak times, lowers peak load demands, extends the lifespan of machinery, reduces total contracted capacity, and saves on electricity costs.

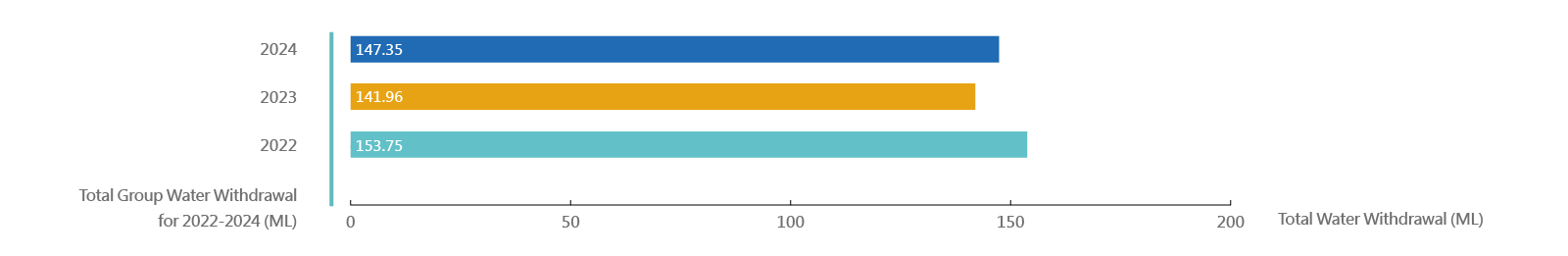

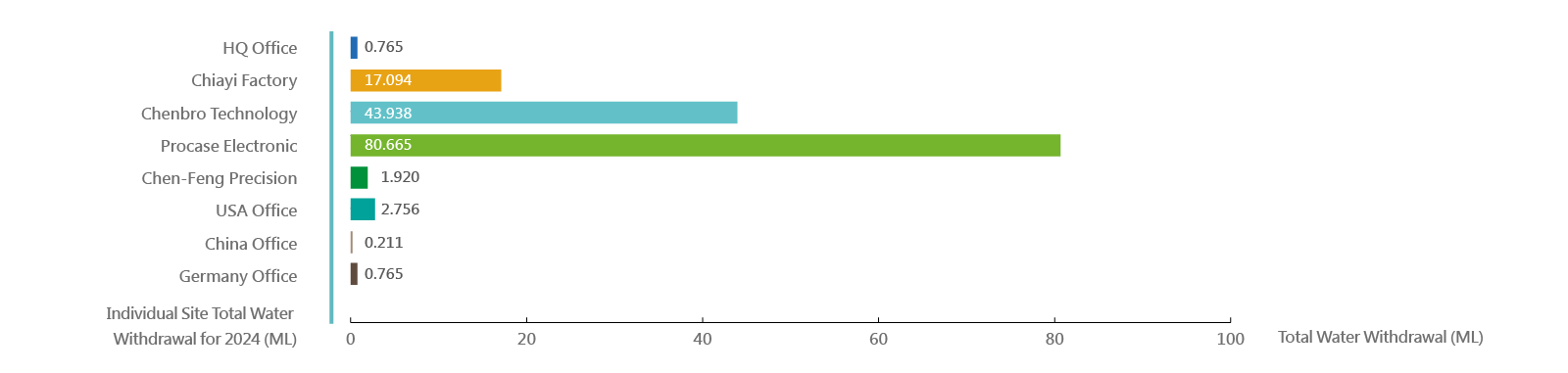

Water Resource Management

In response to the group's environmentally friendly strategies, the factories use water-saving sanitary fixtures with water conservation certifications and set reasonable water pressure for the tap water system, as well as install water resource recycling facilities. The Chiayi factory has set up an ecological retention pond and water channels (with a storage capacity of 111.36 m³), effectively increasing land water retention and temporarily holding floodwaters during rainfall. The building is equipped with a rainwater recycling system (with a capacity of 1060 m³) that collects rainwater from the roof and directs it into the infrastructure, treating it for use in irrigation. This system is also paired with rainwater sensors to conserve irrigation water, thereby reducing the group's water consumption and enhancing water resource management. In 2024, Chenbro's total water intake was 147.35 million liters. Water intensity, calculated by dividing total water intake by annual revenue, was 0.010 for 2024.

Green Products

Responsible Sourcing of Minerals Declaration

CHENBRO warrant that the products are complies with Responsible Sourcing of Minerals:

Not sourcing Conflict Minerals: Tantalum (Ta), Tin (Sn), Tungsten (W) and Gold (Au) from conflict areas of the OECD Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas or illegally taxed on trade routes.Not sourcing Cobalt (Co), Copper (Cu), Graphite (natural)【C (natural)】, Lithium (Li), Mica (Mca) and Nickel (Ni) getting from illegal behavior like coercion, oppression of labor, abuse of child workers or destruction of ecosystem. Conducting supply chain survey about the source of minerals to fulfill corporate social responsibility.